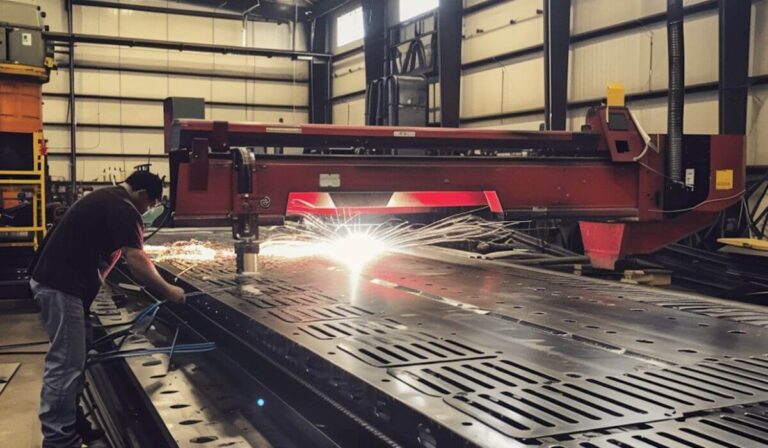

CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape, providing precision and efficiency that traditional methods cannot match. The demand for CNC machining services in Mississippi is rising, driven by industries ranging from aerospace to medical devices. This blog post explores the significance of CNC machining in Mississippi, focusing on the custom solutions available and how they are shaping the future of manufacturing in the region.

Understanding CNC Machining

CNC machining is a manufacturing process that utilizes computer-controlled machines to create parts and components with high precision. This technology allows for intricate designs and complex geometries to be produced consistently and accurately. The process involves using various tools, such as lathes, mills, and routers, which are programmed to execute specific tasks.

The benefits of CNC machining are numerous:

Precision: CNC machines can operate with tolerances as tight as ±0.0001 inches, ensuring that every part meets exact specifications.

Efficiency: Automated processes reduce production time and minimize human error, allowing faster turnaround times.

Flexibility: CNC machining can accommodate various materials, including metals, plastics, and composites, making it suitable for diverse applications.

Customization: With CNC technology, manufacturers can easily modify designs and produce custom parts tailored to specific needs.

The CNC Machining Landscape in Mississippi

The CNC machining landscape in Mississippi is characterized by a diverse array of industries leveraging advanced manufacturing technologies to enhance productivity and precision. With a growing emphasis on automation and efficiency, businesses across the state are increasingly adopting CNC machining techniques to streamline their operations. This shift is particularly evident in sectors such as aerospace, automotive, medical devices, and industrial equipment, where the demand for high-quality, custom parts is paramount.

CNC machining allows manufacturers to produce complex components with tight tolerances, which is essential for applications that require reliability and performance. The ability to quickly adapt designs and produce prototypes has made CNC machining an invaluable tool for innovation. As companies strive to remain competitive, the integration of CNC technology enables them to respond swiftly to market demands and customer specifications.

Moreover, Mississippi’s skilled workforce plays a crucial role in the success of CNC machining operations. With a focus on continuous training and development, machinists and engineers in the state are equipped with the knowledge and skills needed to operate sophisticated CNC equipment. This expertise not only enhances the quality of the finished products but also fosters a culture of precision and excellence within the manufacturing sector.

As the landscape evolves, the future of CNC machining in Mississippi looks promising, with ongoing advancements in technology and materials. The state’s commitment to embracing these innovations positions it as a key player in the national manufacturing arena, ensuring that local industries can thrive in an increasingly competitive global market.

Custom CNC Machining: Meeting Diverse Needs

One of the standout features of CNC machining in Mississippi is the ability to provide custom solutions tailored to specific industry requirements. Here are a few sectors benefiting from custom CNC machining:

Aerospace: The aerospace industry demands precision and reliability. CNC machining allows manufacturers to produce lightweight, high-strength components that can withstand extreme conditions.

Medical Devices: In the medical field, precision is critical. Custom CNC machining enables the production of intricate components for devices such as surgical instruments and implants. The ability to maintain tight tolerances ensures that these components function correctly and safely.

Automotive: The automotive industry relies on CNC machining for various components, from engine parts to interior fittings. Custom solutions help manufacturers reduce weight and improve performance while maintaining safety standards.

Industrial Equipment: CNC machining is essential for producing parts for machinery and equipment used in various industries. Custom solutions ensure that these components meet the specific needs of each application, enhancing efficiency and functionality.

The Process of Custom CNC Machining

The process of custom CNC machining typically involves several key steps:

Design: The first step is to create a detailed design of the part or component. This can be done using CAD (Computer-Aided Design) software, which allows for precise modeling of the desired shape and dimensions.

Programming: Once the design is finalized, it is translated into a format that the CNC machine can understand. This involves creating a program that specifies the tools to be used, the order of operations, and the exact movements required.

Machining: The CNC machine is set up with the appropriate tools and materials. The program is loaded, and the machine begins the machining process, executing the programmed instructions to create the part.

Quality Control: After machining, the finished part undergoes rigorous quality control checks to ensure it meets the specified tolerances and quality standards. This may involve measuring dimensions, inspecting surface finishes, and conducting functional tests.

Finishing: Depending on the application, additional finishing processes may be required, such as deburring, polishing, or coating, to enhance the part’s performance and appearance.

The Future of CNC Machining in Mississippi

As technology continues to advance, the future of CNC machining in Mississippi looks promising. Innovations such as additive manufacturing and advanced materials are expected to further enhance the capabilities of CNC machining. Additionally, the growing emphasis on sustainability and eco-friendly practices is likely to influence the industry, leading to the development of more efficient machining processes and materials.

Mississippi’s CNC machining sector is poised for growth, driven by the increasing demand for custom solutions across various industries. As businesses seek to improve their manufacturing processes and deliver high-quality products, CNC machining will play a crucial role in shaping the future of production in the state.

Conclusion

CNC machining is revolutionizing the manufacturing landscape in Mississippi, offering precision, efficiency, and customization that traditional methods cannot match. As industries continue to evolve, the demand for high-quality CNC machining services will only increase. Companies like Steampunkfab are leading the charge, providing innovative solutions that meet the diverse needs of local businesses.

If you’re looking to enhance your manufacturing capabilities with custom CNC machining, consider exploring the services offered by local experts. For more information on how custom CNC machining can benefit your business, visit steampunkfab.com and discover the possibilities today!