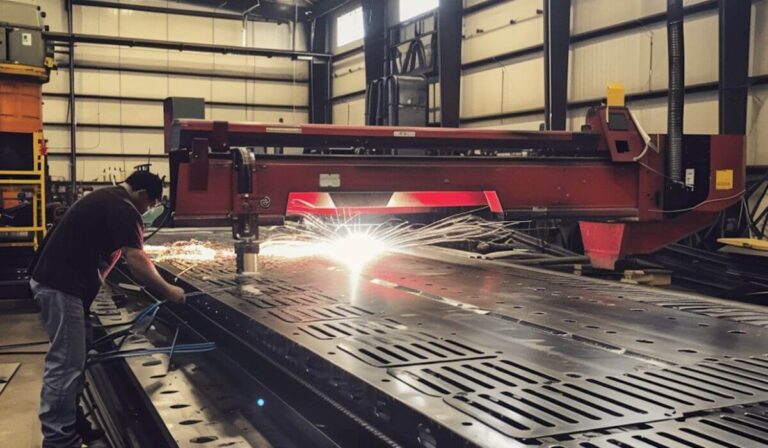

Metal fabrication plays a crucial role in various industries, providing the necessary components and structures needed for manufacturing, construction, and more. Metal fabrication services Mississippi are in high demand, supporting local businesses and industries with quality materials and expert craftsmanship. This article will explore the top five industries that rely heavily on these services and highlight the significance of metal fabrication in their operations.

Understanding Metal Fabrication

Metal fabrication refers to the process of creating metal structures and components from raw materials. It involves cutting, bending, assembling, and welding metal parts to form a finished product. This process can be customized based on the specific requirements of different industries, making it a vital resource for various sectors.

1. Construction Industry

The construction industry is one of the primary sectors that depend on metal fabrication services. Builders and contractors require metal components for various projects, including residential homes, commercial buildings, bridges, and highways. Fabricated metal products such as beams, columns, and reinforcements provide structural integrity and support to construction projects.

Key Applications in Construction

- Steel Beams and Columns: Essential for supporting large structures.

- Reinforcement Bars: Used in concrete to enhance strength and durability.

- Metal Roofing and Siding: Provides weather protection and aesthetic appeal.

The reliability and quality of metal fabrication are critical in ensuring the safety and longevity of construction projects.

2. Manufacturing Industry

Metal fabrication is a cornerstone of the manufacturing industry. Various products, from automotive parts to machinery components, are created through metal fabrication processes. Manufacturers rely on precision fabrication to produce high-quality parts that meet strict specifications.

Key Applications in Manufacturing

- Automotive Components: Engine parts, frames, and exhaust systems.

- Machinery Parts: Gears, brackets, and custom components.

- Consumer Goods: Metal furniture, appliances, and tools.

Without skilled metal fabrication, the manufacturing process would face significant challenges in meeting consumer demands and maintaining product quality.

3. Aerospace Industry

The aerospace industry demands precision and quality, making metal fabrication an essential service. Components used in aircraft and spacecraft must meet stringent safety and performance standards. Fabricators create parts that are lightweight yet strong, crucial for flight efficiency.

Key Applications in Aerospace

- Airframe Components: Wings, fuselage, and tail sections.

- Engine Parts: Turbine blades and housings.

- Landing Gear: Critical for aircraft safety during takeoff and landing.

Aerospace metal fabrication requires specialized skills and advanced technology to ensure that every part performs reliably under extreme conditions.

4. Oil and Gas Industry

The oil and gas industry also relies on metal fabrication for constructing pipelines, drilling rigs, and storage facilities. Fabricated metal components must withstand harsh environments, including extreme temperatures and pressures. Therefore, high-quality materials and precise engineering are paramount.

Key Applications in Oil and Gas

- Pipelines: For transporting crude oil and natural gas.

- Storage Tanks: Essential for holding various petroleum products.

- Drilling Equipment: Components used in drilling rigs and platforms.

Metal fabrication services in this industry focus on durability and reliability, ensuring safe and efficient operation in critical environments.

5. Renewable Energy Industry

As the world shifts towards sustainable energy, the renewable energy sector is experiencing significant growth. Metal fabrication plays a crucial role in manufacturing components for wind turbines, solar panels, and other renewable energy systems. The need for reliable and efficient energy sources drives demand for quality fabricated metal products.

Key Applications in Renewable Energy

- Wind Turbines: Towers, blades, and gearboxes.

- Solar Panel Frames: Structural supports for photovoltaic systems.

- Hydroelectric Components: Gates, turbines, and penstocks.

The renewable energy industry’s reliance on metal fabrication services highlights the importance of innovation and quality in producing components that contribute to a greener future.

The Importance of Quality in Metal Fabrication

In industries where safety and performance are critical, the quality of fabricated metal products cannot be overstated. Using high-grade materials and adhering to industry standards is essential for ensuring that components function correctly and safely. Companies must prioritize working with reputable metal fabrication services to guarantee that their products meet all necessary specifications.

Choosing the Right Metal Fabrication Partner

Selecting the right metal fabrication partner is vital for any business relying on these services. Here are some tips for choosing a reliable provider:

- Evaluate Experience: Look for companies with a proven track record in the industry.

- Check References: Customer testimonials can provide insights into the quality of service and products offered.

- Assess Capabilities: Ensure the fabricator has the necessary equipment and expertise to handle your specific needs.

- Review Certifications: Certifications demonstrate a commitment to quality and industry standards.

By taking these factors into account, businesses can find a partner that will help them succeed.

Final Thoughts

Metal fabrication services are essential across various industries, providing the necessary components and structures that enable operations to run smoothly. Exploring metal fabrication services opens the door to numerous possibilities. Collaborating with experienced providers can enhance project outcomes and contribute to industry success. Take the time to research and connect with reputable fabricators to meet your metal needs effectively.